ERW Line Pipe

Overview

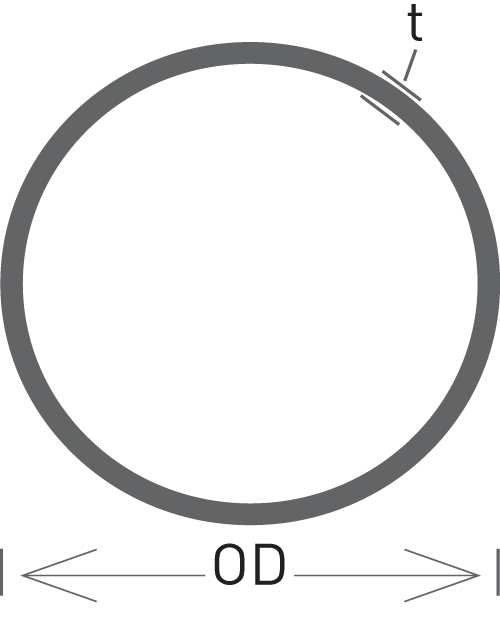

ERW stands for Electric Resistant Welded, they are round pipes manufactured by cold forming a flat strip and passing it through forming rollers to create longitudinal welds. ERW pipe is extremely versatile and it is widely used for various structural applications.

Features and Benefits of ERW Line Pipe

- High efficiency

- Can meet low- and high-pressure requirements

- No fusion metals used during the manufacturing process

- Extremely strong and durable

Typical Uses of ERW Line Pipe

- Structural fabrication

- Steel piling manufacture

Relevant Standards

- AS/NZS 4041: Class 2 pipe work in underground applications

Specification for ERW Line Pipe

Wall thickness shown in unshaded areas

Weight shown in shaded areas are kg/m

Not all branches stock the sections below. 12m lengths are standard. Non-stock (>400NB) & Custom length items are subject to Minimum Order Quantities (MOQ’s). Contact your local Steelforce branch to confirm product availability.

- End Preparation - Bevelled Ends in Accordance with API specifications

- All weights (kg/m) are nominal - some minor variation is expected