Technical Specifications

Steelforce takes great pride in offering a competitive product range of a high and consistent quality.

Manufacturing Standards

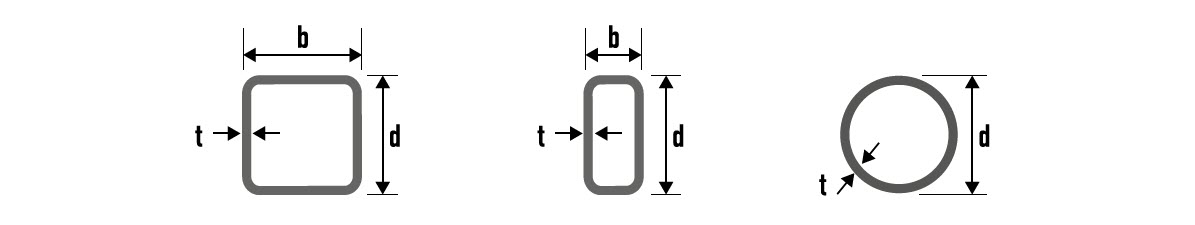

Pipe & Tube Tolerances

Hollow Sections - Standard Grades include: C250, C250L0, C350 * C350L0.

Notes

- Where the diameter to thickness exceeds 100, the tolerance on out-of-roundness becomes the subject of agreement between the manufacturer and purchaser.

- The tolerance on concexity and concavity is independent of the tolerance on external dimensions.

- The straighness tolerance applies to straightness in any one plane.

- In lieu of any other requirement, the specified mass is considered to be the nominal mass.

Profile Standards

Profiles are supplied as cold rolled and electroplated.

Chemical Composition - % Max

Note — The carbon equivalent (CE) is determined in accordance with the equation from AS/NZS 1163:2016 - Grade:C350LO

CE = C + Mn/6 + (Cr+M0+V)/5 + (Ni+Cu)/15

Mechanical Properties

Note — Test specimens are to be taken longitudinally from a major flat portion of the section. Test frequency is as per AS/NZS 1163:2016.

The yield, tensile and elongation will be determined in accordance with AS 1391, with samples artificially aged to a temperature of 180 degrees for a period of not less than 15 minutes.

Impact Testing

Impact testing as described in Section 10 of AS/NZS1163:2016 is performed at O°C in accordance with AS 1544.2 on all profiles (flats, angles and channels) with a nominal thickness of 6mm or greater.

Coating Thickness

All profiles are electroplated to a thickness of 50 grams per square metre per side (ZIOO). The profiles are then coated with a solvent based Clearcote to a thickness averaging between 14 and 20 microns.

Surface Finish

Product shall be free from lamination, surface flaws and other defects detrimental to its use for structural purposes.

Length

Angles and Channels are available in 6 and 9 metre lengths. Flats are available in 6 metre lengths.

Non-standard lengths by inquiry.

End Condition

Profiles are supplied with mill cut ends. End coding is applied in accordance with AS/NZS 4496:1997.

Length Capabilities

Overall manufactured length capabilities of products are as follows. Not all products are able to be rolled to the minimum and maximum as listed below – refer to your Sales Representative for more information.

- Minimum Rolling Length 5.0m

- Maximum Rolling Length 12.0m

See Mill Processing for lengths shorter than 5.0m.

Special Lengths

Our manufacturers can roll special length orders within its manufactured length capabilities. A

minimum order quantity (MOQ) may apply. See Mill Processing below or lengths

shorter than 5.0m.

Mill Processing

Steelforce offers a pack cutting service if you require lengths less than the minimum

anufactured length capability (5.0m). Please contact your local sales representative

or pricing, terms and conditions.

Finishes

- DuraGal®

- Painted - Blue, Black, Red

- Pre-Gal

- NOPC (no oil, paint or coatings)

- Hot Dip Galvanised

GalForce Profiles Coating has a Z100 zinc coating which equates to 50 grams per square metre per side.

DuraGal coating or equivalent Pre-Gal coating has a Z200 zinc coating which equates to 100 grams per square metre per side.

Pre-Gal and DuraGal sections are coated with a clearcoat finish.

ZB135 DuraGal Plus pricing, MOQs and lead times availalbe upon request.

Precision Tube Standard

Manufacturing Tolerances

Chemical composition

The carbon equivalent (CE) is determined in accordance with the equation from

AS 1450-2007, i.e. CE = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

Full chemical analysis to be shown on Test Certificates.

Mechanical Properties

The mechanical tests - yield, tensile and elongation - will be carried out in accordance with AS1391. Prior to tensile testing, the test pieces shall be aged by heating to a temperature between 150°C and 200°C for not less than 15 min.

Elongation results shall be reported on a gauge length Lo = 5.65√So where So is the original cross-sectional area of the test piece before testing.

Test specimens are to be taken longitudinally from a major flat portion of the section.

Test frequency is as per AS 1450-2007.

Finish Coating

RHS and SHS - blue paint.

Pipe - black paint.

Pregal - zinc coated coil with Clearcote coating applied.

Coating Thickness

Painted product - minimum paint thickness of 9 microns

Pregal product - average zinc thickness of 50 grams per square metre per side (Z100).

- minimum Clearcote thickness of 9 microns.

Surface Finish

Product shall be free from lamination, surface flaws and other defects detrimental to its use.

Length tolerance

-0mm + 15mm (Standard lengths 6.5 and 8 metres)

End Condition

Products are supplied with mill cut ends with burr held to a minimum. End coding is applied in accordance with AS/NZS 4496:1997.

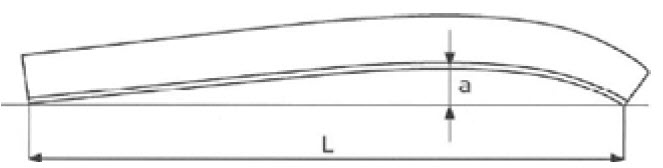

Straightness

The maximum permissible variation from straightness shall not exceed: - Specified length 500

Corner Radius

Outside corner radius is 2 x gauge ± 0.5mm, i.e. 2t ± 0.5mm

Squareness of Sides

Maximum permissible is 90o ± 1o

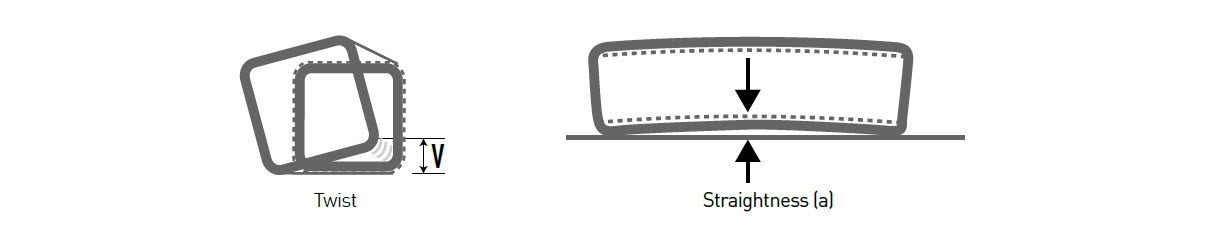

Twist

Maximum permissible is 2 mm + 0.5 mm/m length

External Dimensions

RHS and SHS - ± 1%

CHS - + 0.1mm, - 0.3mm

Gauge

The maximum variation in thickness of all products will not exceed ± 10%.

Concavity/Convexity

Maximum 0.8% or 5mm, whichever is greater

Cold Flattening Test Piece

The test piece shall be taken in the form of a cross-section from one end of a finished length of a circular tube which contains a longitudinal weld. The length of the test piece shall be not less than 40 mm. All burrs shall be removed before testing. The test piece shall be cut in the transverse direction.

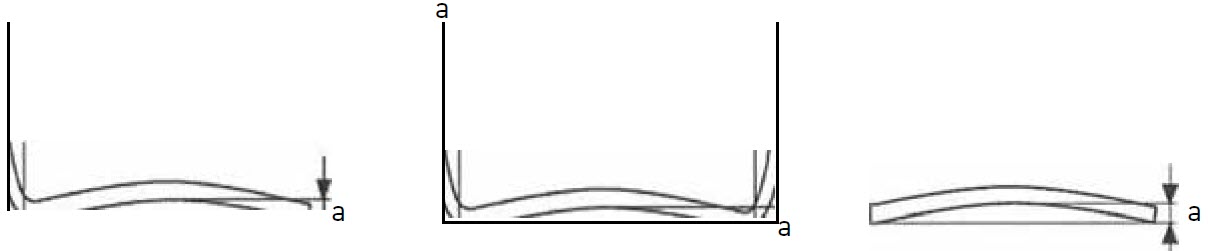

Straightness

Profiles will be supplied to a straightness of Imm in 500mm measured as follows:-

The straightness will be calculated by measuring the horizontal deviation (a) over the ordered profile length (L), i.e. (a) L/500.

Corner Radius

Corner radius is 2 times gauge plus or minus 0.5mm

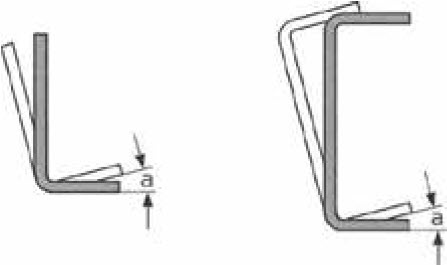

Squareness

The maximum out of squareness of a profile will be plus or minus 1.5 degrees.

Twist

The maximum angle of twist of a profile (a) will be 1 degree in 1 metre.

Flatness of Sides

The flatness of any side (a) will be limited to less than 0.8% of the width of that side or 0.5mm, whichever is the greater.

Dimensions

The maximum variation in leg and web dimensions of angles and channels will not exceed 1.5mm.

For the maximum variation in width of flats refer section 16 below.

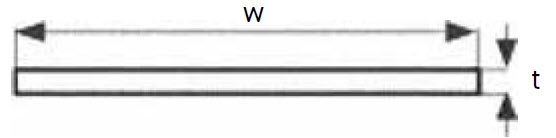

Width of Flats

The variation of the width (W) dimension of flats, where (t) is the designated thickness, are as

follows:-

Gauge

The maximum variation in thickness of all profiles will not exceed plus or minus 10%.